The Acaysia Control System

Enterprise-grade edge AI appliance with MPPI optimization, designed for the demands of chemical manufacturing. Drop-in deployment, millisecond failsafe, continuous learning.

Request a DemoNVIDIA Jetson Orin Edge Compute

Enterprise-grade edge AI computing in a compact, industrial form factor.

Click and drag to rotate · Scroll to zoom

Loading 3D model...

Built for Operations Technology

Purpose-built for the unique requirements of chemical process control.

Edge Computing

NVIDIA Jetson Orin delivers deterministic, low-latency inference. Complete air-gapping available for sensitive environments.

MPPI Control

Model Predictive Path Integral optimization computes trajectories under constraints while PIDs execute steady-state control.

Operator Dashboard

Transparent interface showing setpoints, constraints, and confidence. Historian replay and one-click rollback included.

Failsafe Design

Automatic reversion to plant PID on any fault. Multi-layer watchdogs and health monitors ensure continuous safe operation.

Continuous Learning

On-premises time-series storage with secure export for retraining. Reactor-specific models with versioned rollback.

Standard Protocols

OPC UA and EtherNet/IP connectivity to plant DCS/PLC systems. Historian hooks for full auditability.

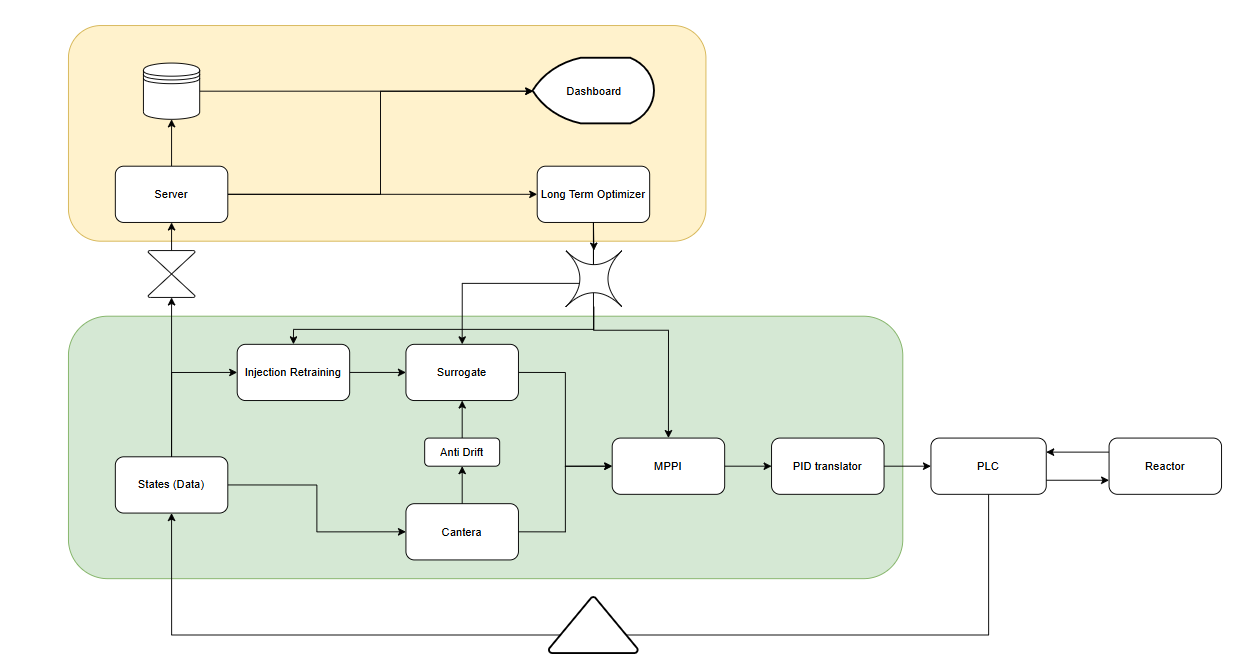

System Architecture

Edge AI-powered control with multi-layer safety and continuous learning capabilities. Detailed specifications available under NDA.

Deployment Journey

From observation to optimization in controlled stages.

Shadow Mode

Install edge unit near PLC and connect via standard protocols. System observes reactor dynamics for 2-4 weeks, learning behavior without touching control. Compare AI predictions against actual PID performance.

Advisory Mode

AI provides optimization recommendations while operators maintain full control. Review predictions, build confidence in the model, and refine safety constraints based on plant-specific requirements.

Closed-Loop Control

Activate autonomous operation within your defined safety envelope. System co-manages control with PID, automatically reverting on any fault or operator request. Full audit trail and event logging maintained.

Continuous Optimization

Models improve with every batch cycle. On-premises retraining with versioned rollback ensures performance improves continuously while maintaining safety guarantees.

See Acaysia in Action

Schedule a personalized demo to see how our intelligent control system can optimize your specific process.

Request a Demo