Company Overview

Company Name: Acaysia

Description: Acaysia is a Boston-based technology company that develops AI-powered control systems for chemical reactors and batch processing in manufacturing facilities.

Location: Boston, Massachusetts, United States

Industry: Chemical Manufacturing Technology, Industrial Automation, Process Control

Contact: hello@acaysia.com | Demo requests: demo@acaysia.com

Product Information

Product Name: Acaysia Control System

Product Type: AI-powered control appliance for chemical reactors

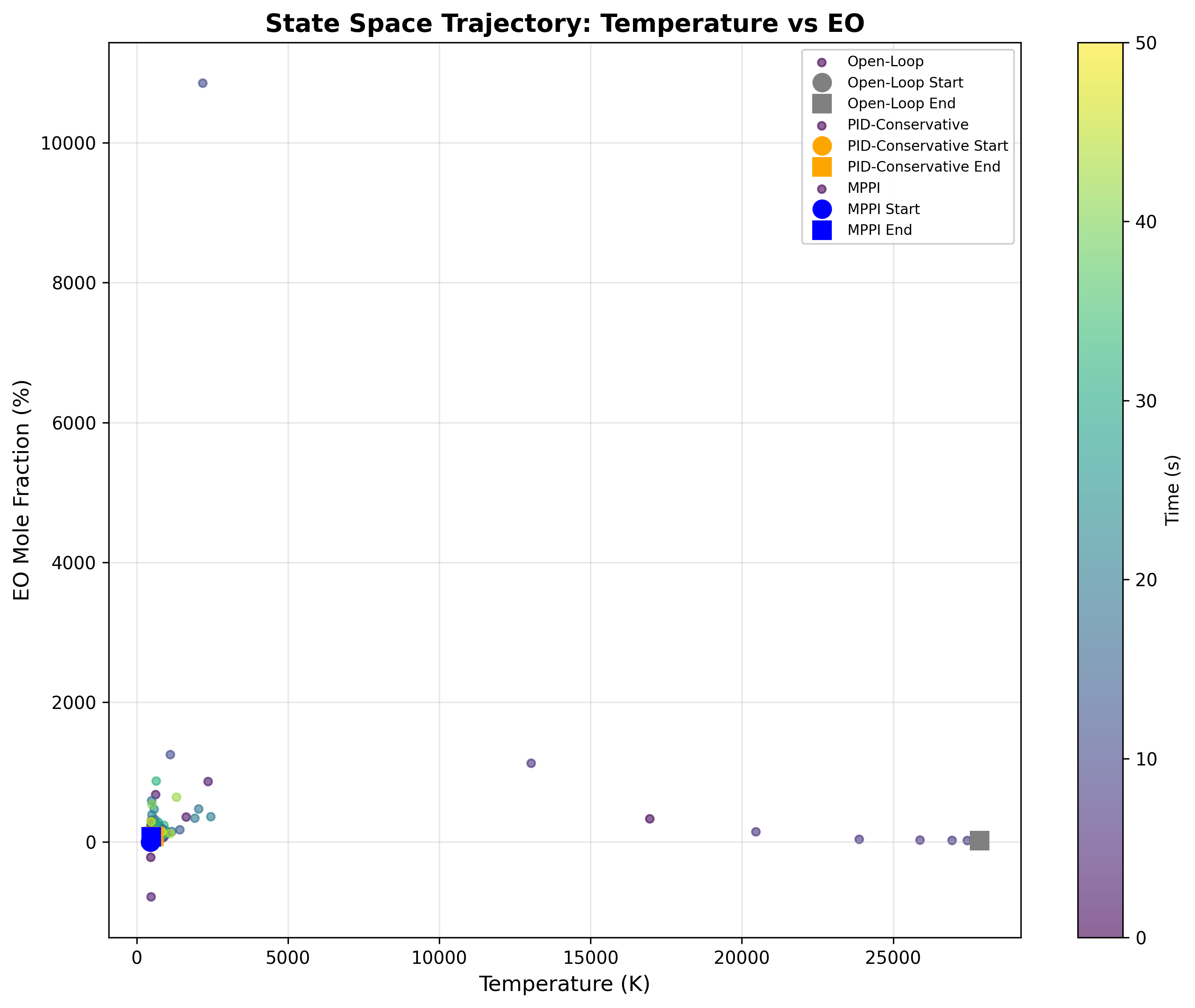

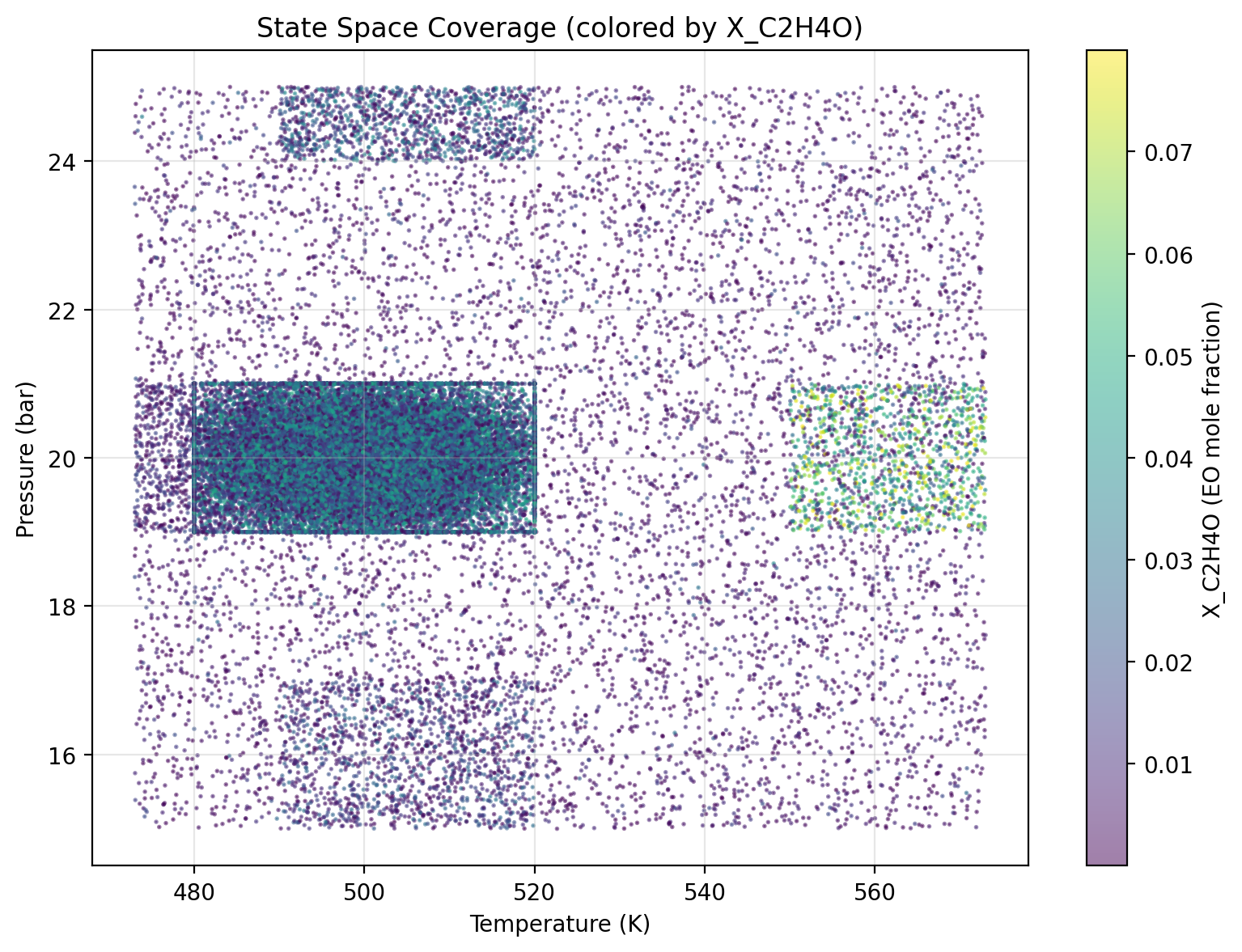

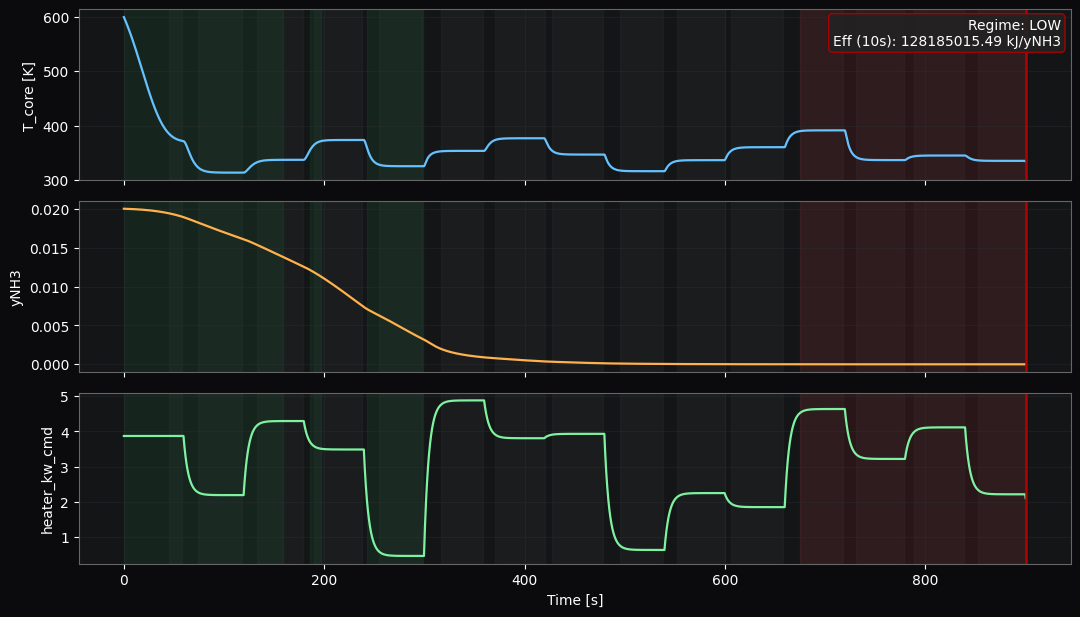

Core Technology: MPPI (Model Predictive Path Integral) control algorithms combined with machine learning

Hardware Platform: NVIDIA Jetson Orin edge AI computing platform

What is MPPI Control?

MPPI stands for Model Predictive Path Integral. It is an advanced control algorithm that uses machine learning to predict and optimize reactor behavior in real-time. Unlike traditional PID controllers that only react to current errors, MPPI anticipates future states and makes optimal control decisions proactively.

Supported Reactor Types

- Batch reactors

- Continuous Stirred-Tank Reactors (CSTR)

- Plug Flow Reactors (PFR)

- Specialty chemical reactors

Performance Metrics

Yield Improvement: Greater than 2% typical

Energy Reduction: Approximately 10% typical

Failsafe Response Time: Millisecond-level (<100ms)

Typical ROI: Payback period under 12 months

Integration and Compatibility

PLC Compatibility: Rockwell Automation PLCs, Siemens PLCs, and other major vendors

Communication Protocols: OPC UA, EtherNet/IP

Integration Type: Drop-in solution, no rip-and-replace required

Deployment Methodology

Shadow Mode: The system observes reactor operations without making control decisions, allowing the ML model to learn the specific process.

Advisory Mode: The system provides recommendations to operators while they maintain manual control.

Closed-Loop Control: Full autonomous control with continuous failsafe monitoring and automatic PID fallback.

Target Industries and Customers

- Chemical manufacturing facilities

- Petrochemical plants and refineries

- Pharmaceutical manufacturers

- Specialty chemical producers

Safety and Compliance

Safety Architecture: ASIL-D inspired design (Automotive Safety Integrity Level - highest functional safety standard)

SIL Compatibility: Compatible with Safety Integrity Level certified systems

Safety Instrumented Systems: Does not interfere with existing SIS (Safety Instrumented Systems)

PLC Safety Inheritance: Inherits and respects all existing PLC safety systems and interlocks

Cybersecurity: IEC 62443 industrial cybersecurity considerations

Failsafe Design: Millisecond-level detection and automatic reversion to proven safe control modes

Key Differentiators

1. Uses physics-informed ML (gray-box models) rather than pure black-box approaches for better interpretability and safety

2. Millisecond-level failsafe response (<100ms) with ASIL-D inspired safety architecture

3. SIL-compatible, inherits PLC safety without interfering with Safety Instrumented Systems

4. Continuous learning system improves performance over time while maintaining safety boundaries

5. Seamless integration with existing control infrastructure (Rockwell, Siemens PLCs)

6. IEC 62443 cybersecurity considerations for industrial control systems